The Ultimate Guide To precision machining

When you structure a part, it’s as vital to consider wall thickness as The great thing about the design.

With this process, portion complexity isn't going to maximize portion Value, supplying you with the pliability to supply extremely intricate conï¬gurations reliably and affordably. Tooling is speedy and cheap, earning the procedure ideal for prototyping; on the other hand, the flexibleness, repeatability, and precision mean it is Preferably fitted to medium and significant volume manufacturing in addition. Common lead moments are three weeks and expedited support is usually rotated in a couple of days.

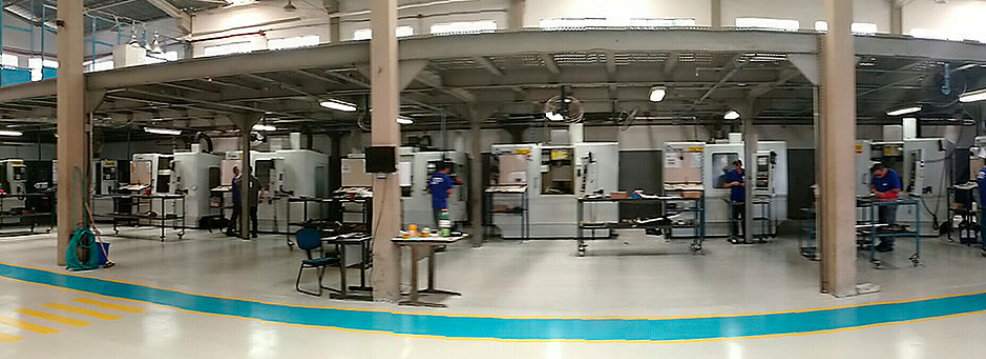

With a highly trained generation and engineering staff members, we provide precisely the same degree of services to big and compact organizations alike from Fortune 500s to impressive startups.

A Review Of precision machining

C-body mill These are definitely more substantial, industrial output mills. They function a knee and glued spindle head that may be only mobile vertically. They are generally way more powerful than a turret mill, that includes a separate hydraulic motor for integral hydraulic energy feeds in all Instructions, plus a 20 to fifty horsepower motor.

What is the precision of the quantity? The volume of digits in a very variety is named precision of the quantity.According to the precision required, the range is quantized togive the final quantity.

BP Precision Machining provides a full array of pressure testing companies, each high and reduced, to fulfill all force tests requirements of our prospects. Our stress tests providers involve proof tests as many as 30,000 PSI.

These devices are operated by specialised and properly trained machinists. The precision machining method entails a reducing Resource that eliminates substance with the workpiece. In order for the chopping Instrument to do its career, it needs to be moved in directions specified to create the correct Reduce. This Major movement is called the “reducing velocity.†The workpiece can even be moved, referred to as the secondary motion of “feed.†Together, these motions as well as the sharpness from the reducing tool allow the precision device to work. Learn More:

Adding your portion to your section library permits other buyers to search for your portion in our reference portion library. Your portion is going to be submitted to CustomPartNet for critique (an element image is needed) and whether it is permitted It'll be included into the library.

A Simple Key For precision machining Unveiled

one : a tool with moving sections that does some desired operate when it is supplied with electricity a sewing equipment

a. A tool applied to create a stage impact, Primarily a mechanical suggests of lowering an actor onto the stage.

What exactly the "managed" Component of the definition implies will vary, but it almost always implies the usage of equipment resources (Besides just electrical power equipment and hand instruments).

Drilling operations are operations wherein holes are created or refined by bringing a rotating cutter with reducing edges in the decreased extremity into contact usinagem de precisão with the workpiece. Drilling operations are carried out primarily in drill presses but from time to time on lathes or mills.

Fascination About machining

It is evident that milling devices as a distinct course of machine Instrument (individual from lathes jogging rotary information) first appeared concerning 1814 and 1818. The centers of earliest growth of accurate milling machines had been two federal armories of the U.S. (Springfield and Harpers Ferry) along with the assorted private armories and inside contractors that shared turnover of competent workmen with them. Concerning 1912 and 1916, Joseph W. Roe, a highly regarded founding father of equipment tool historians, credited Eli Whitney (among the list of personal arms makers outlined higher than) with creating the very first correct milling machine.[18][19] By 1918, he regarded it "In all probability the primary milling machine at any time constructed—certainly the oldest now in existence […].